Enterprise spirit:Based on customers, connect to the future

Company policy:Huan'an is the leader, quality first, people-oriented, continuous operation

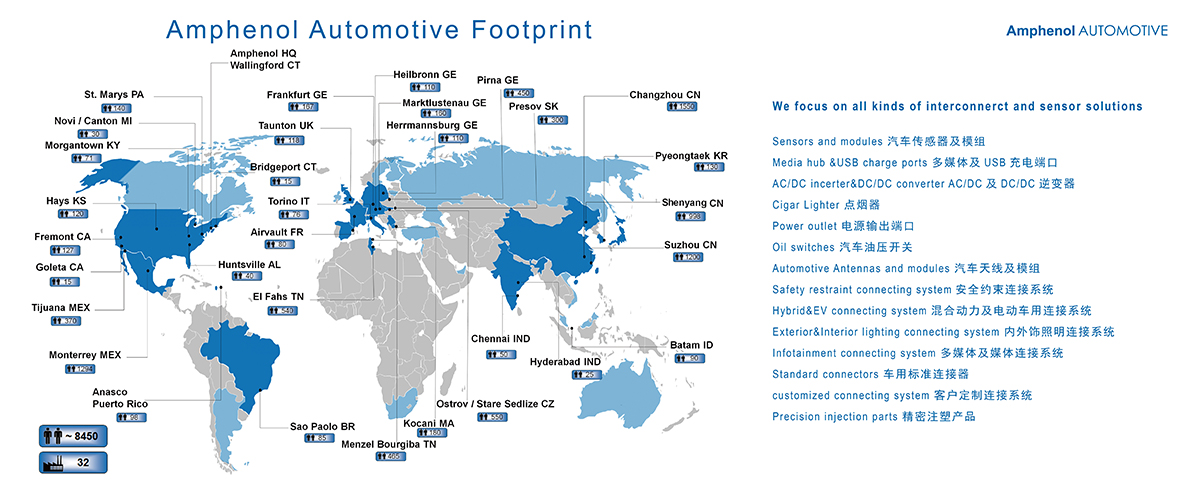

Amphenol Group was founded in 1932 and is currently the second largest supplier of connectors and sensors in the world. Its products cover various fields such as automobiles, mobile communication equipment, IT and data communication, mobile communication base stations, broadband, and industrial equipment.

Amphenol Group's research and production bases are widely distributed in the Americas, Europe, Asia, Australia, and Africa.

Amphenol Automotive Connection System (Changzhou) Co., Ltd. is a wholly-owned subsidiary of Amphenol Group in China, affiliated with Amphenol Automotive Products Group, established in 2004. After more than ten years of effort, six major business units and ten product groups have been formed, covering safety airbag connectors and wiring harnesses, automotive seat belt wiring harnesses, automotive sensor connectors and wiring harnesses, automotive interior and exterior lighting connectors and wiring harnesses, new energy vehicle connectors and wiring harnesses, automotive sunroof wiring harnesses, automotive transmission wiring harnesses, automotive information and entertainment system wiring harnesses, standard connectors Hydraulic switches and other small wiring harnesses for different functional parts of automobiles. The products produced are in a strong leading position nationwide in terms of market share, technological content, and quality.

In the past decade or so, our company has faced an exceptionally fierce market environment, overcome difficulties, worked hard, and achieved remarkable results in rapid business development. In 2019, product sales exceeded 1.158 billion yuan, with a total of over 1500 employees and a factory area of over 39000 square meters, making due contributions to the development of the local economy in Changzhou.

Our company adopts advanced production and testing equipment and processing technology from around the world, implements the concept of lean production, and produces various types of small car wire harnesses and standard connectors. We produce over 2000 product numbers annually, with an annual output of over 160 million pieces. The main production and testing equipment exceeds 600 units (sets), including integrated fully automatic wire breakage, wire stripping, waterproof ring threading, crimping, assembly equipment, fully automatic coaxial cable harness processing equipment, fully automatic glue filling machine, fully automatic injection molding machine, fully automatic airbag connector production line, automatic resistance welding machine, automatic tape wrapping machine, semi-automatic crimping machine, plastic ultrasonic welding machine, high-precision image detection equipment, Multi functional testing equipment and testing bench.

Our company has advanced laboratory capabilities and can complete various conventional measurements and tests. We have programmable high-precision optical measurement equipment, ultra deep precision microscope, imported coating film thickness measurement equipment, salt spray testing machine, high and low temperature test chamber, and loaded three-dimensional vibration testing equipment. It provides a strong guarantee for the production of high-quality products and product research and development.

Our company has strong research and development capabilities, using software such as Pro-E, Solidworks, CATIA, AutoCAD, etc. to design products and perform modeling and finite element analysis. Therefore, a large number of new products are launched on the market every year and hold dozens of invention and utility model patents. Especially in the fields of safety system connectors, nitrogen oxygen sensor connectors, and high current connectors for new energy vehicles, we are in an indisputable leading position in the Chinese market.

In terms of product quality control, our company has passed and maintained the IATF16949/ISO9001 quality assurance system, and is an OEM recognized supplier for General Motors, Volkswagen, Audi, BMW, Dongfeng Nissan, GAC, SAIC, FAW, Great Wall, Changan, Geely, and others. At the same time, according to the VDA6.3/VDA6.5 standards, comprehensive system audits, process audits, product audits, and hierarchical audits are carried out to ensure the provision of high-quality products to customers, and multiple honors have been awarded by customers over the years.

Our company has been focusing on market development and currently has over 380 clients. There are many world-renowned automotive parts manufacturing giants, such as AUTOLIV, ZF, JSS, BOSCH, CONTINENTAL, BROSE, NGK, LG, SAMSUNG, CATL, LEONI, APTIV, VALEO, SUMITOMO, MAGNA, INALF, etc. By collaborating with these well-known large companies, we have further enhanced our reputation in the field of automotive parts.